Model DDX PrePaK

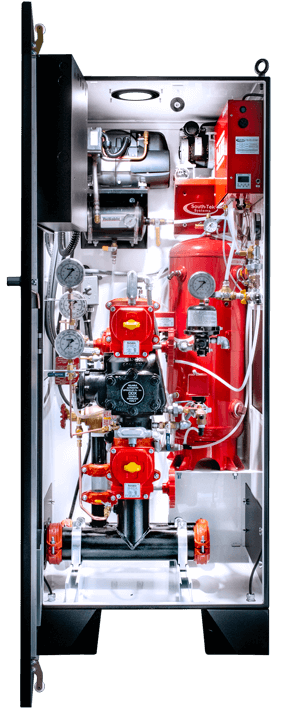

The Cabinet

Cabinet-enclosed Preaction, Dry Pipe, and Deluge Valve Systems

FM Approved as a factory-assembled system

- Powder-coated steel construction

- All sizes fit through a standard 36” (914 mm) doorway

- Lifting eyes

- Access panels on both sides

- Water supply and drain connections on both sides and at common centerlines

- Supply and system pressure gauges as well as (optional) releasing control panel display are visible through the gasketed cabinet door

- Grommets provided for pipe penetrations

- Potter Model RCDS-1 Releasing Circuit Disable Switch—Provides a supervised method of disconnecting the solenoid during system maintenance and service

- All electrical connections consolidated to a factory-wired terminal box

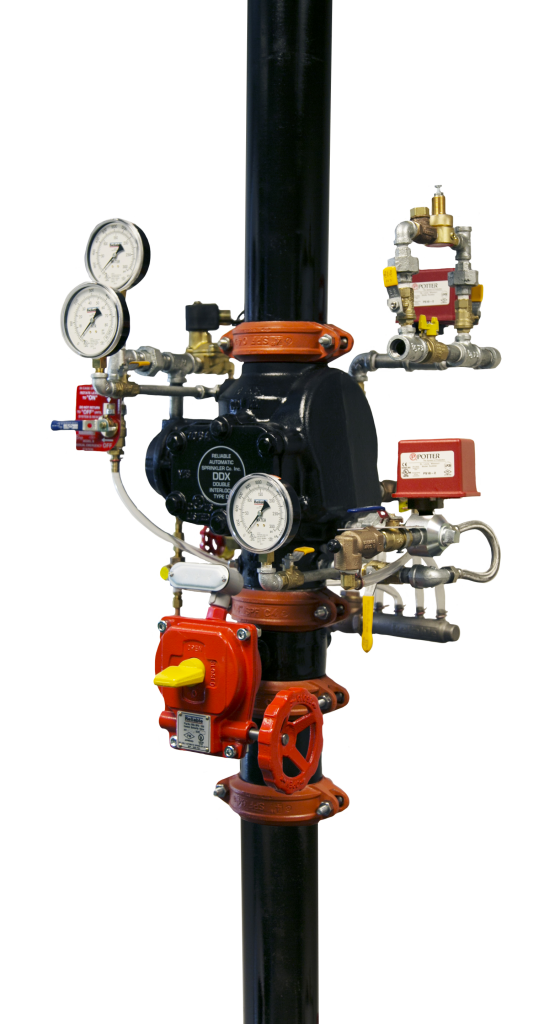

The Heart of the System: The DDX Valve

Integrated South-Tek N2-Blast® Nitrogen Generator

Increase the life expectancy of system piping and components with a South-Tek nitrogen generator

- FM Approved nitrogen generator

- Pressure Swing Adsorption (PSA) technology

- System capacity up to 900 gallons

- Includes AutoPurge System® vent

The Reliable Difference

Assembled in-house. Never outsourced.

Built in Liberty, SC by Reliable.

- Factory-assembled at Reliable’s Manufacturing Headquarters in Liberty, SC.

- A Reliable trained technician assembles and is responsible for each PrePaK.

- Reliable Technicians stand behind their work, so much so, their signature goes on the label.

- Each PrePaK passes Reliable’s rigorous performance testing.

For more information about PrePaK Preaction Systems locate your closest Reliable office or use the form on this page to get in touch with our team.